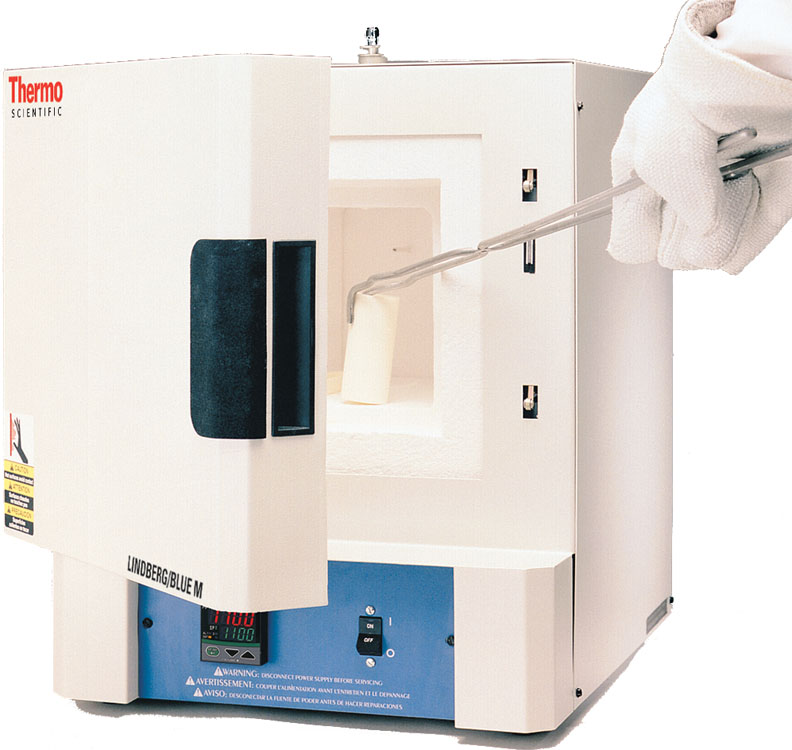

Thermo Scientific Lindberg/Blue M 1.99L C2 Moldatherm Box Furnace

$3,584.00

Thermo Scientific Lindberg/Blue M Moldatherm 1100°C box furnaces feature a choice of microprocessor-based single setpoint or programmable control instrumentation. They are available in four popular chamber sizes to meet the most demanding laboratory applications. These furnaces include unique insulation and heating element composites to minimize outer surface temperatures while maintaining uniform heat distribution within the chamber. Advanced engineering and specialized construction techniques include variable density insulation, double shell cabinets, long-life heating elements and vertical, horizontal side swing or swing down doors.

Thermo Scientific Lindberg/Blue M Moldatherm 1100°C box furnaces feature a choice of microprocessor-based single setpoint or programmable control instrumentation. They are available in four popular chamber sizes to meet the most demanding laboratory applications. These furnaces include unique insulation and heating element composites to minimize outer surface temperatures while maintaining uniform heat distribution within the chamber. Advanced engineering and specialized construction techniques include variable density insulation, double shell cabinets, long-life heating elements and vertical, horizontal side swing or swing down doors.

- Includes the C2 Controller

- Programmable with one (1) stored program of sixteen (16) segments. Each segment includes one ramp and one dwell, so you can program 16 ramp/dwell cycles.

- The ramp is used to vary the heat-up rate to your specified setpoint. The furnace will then dwell (hold the temperature) at a set level for a specified time.

- An LED display simultaneously shows both setpoint and actual furnace temperatures.

- Super Control (Fuzzy logic) suppresses overshooting of temperature

- Customer initiated auto-tune function will adjust and update the PID parameters to the optimum settings for new temperature setpoints

- Selectable self-tuning feature sets best control parameters for the thermal process

- PID control (proportional, integral, derivative) prevents overshoot

- Main power ON/OFF switch on control panel

- Controlled heat-up rate eliminates thermal shock to materials

- Quick heat-up and cool-down rates

- Adjustable high-limit overtemperature protection

- Simultaneous LED display of actual temperature vs. setpoint

- Can be configured to display temperature in either °C or °F

- Unique double wall minimizes exterior surface temperatures for operator safety and energy efficiency

- Side-hinge door for convenient operation and full chamber access

- Long-life Type K thermocouple

- Air vent (1in. dia., top) and air inlet (1/4-inch Male Pipe Thread, rear) for inert atmosphere exchange; will experience some leakage at door

- Removable and replaceable Moldatherm hearth plate supports load and prevents damage due to spillage

- Energy efficient Moldatherm insulation with embedded heating elements

- Safety door switch to interrupt power to heating element when door is opened; protects heating element and minimizes exposure to end-user

Standard Lead Time: 3-4 Weeks

Additional information

| Dimensions | 20 × 15 × 17.5 in |

|---|---|

| Brand | |

| Part No. | |

| Lead Time | |

| Voltage | |

| Power | |

| Frequency |